Reverse Engineering.

Reverse engineering doesn’t just mean 3D scanning or copying a part, it’s much more than this. To create a sympathetic and functional recreation of an existing product requires understanding a wide range of engineering disciplines. At RSL we can provide a turnkey solution from design to manufacture even on complex assemblies.

Call us to discuss your project.

Click here to download PDF.

Using industry leading software and many years of experience we are able to provide reverse engineering services creating CAD models of damaged or worn parts and incorporate desired design intent. 3D scanning is the fastest way to collect real world data and create a CAD model. It is this CAD model that is required for further design or manufacture.

At RSL we have over 20 years’ experience in classic car restoration, and over 10 years in computer aided design. We can reverse engineer your parts and produce low volume runs in a very short timeframe, to a very high standard.

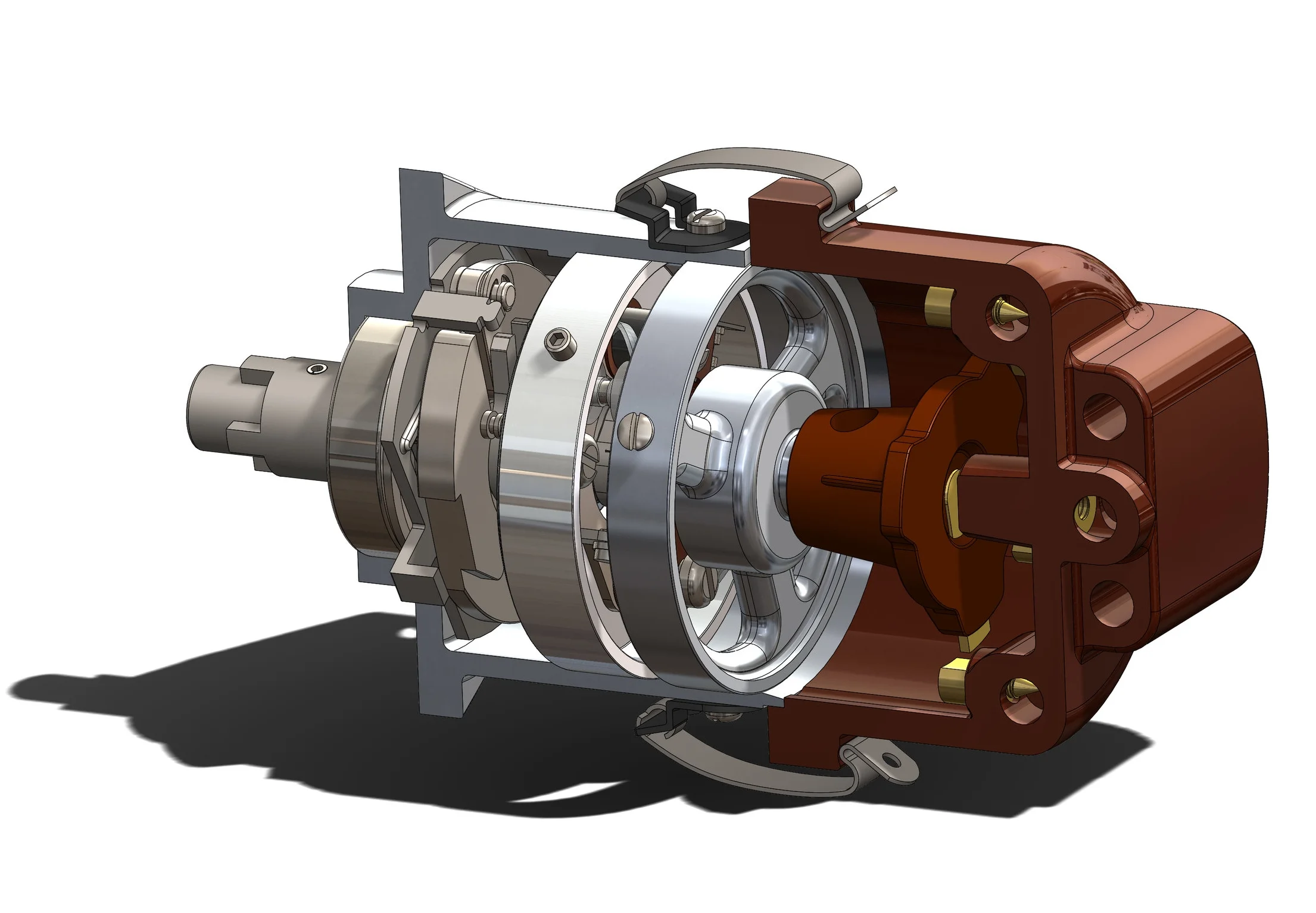

Completly reverse engineered in house

Ferrari 225s Distributor.

This Ferrari 225 is from 1952 and very rare which makes getting parts either very difficult or impossible. The 225 was unable to competitively race due to needing replacement distributors. After trying to source parts was unsuccessful, recreating them was the only option. The first step was to disassemble the existing distributors so each component could be 3D scanned and modelled. Once modelled, we could then look at redesigning some of the internal components to ensure that all those moving parts fit together with the correct tolerances. The parts were then put together as an assembly in a 3D CAD program to ensure the mechanism worked correctly. We could then confidently manufacture the parts. The parts were then assembled and the finished item was then tested on a distributor testing machine to check and setup the finished product. The final test involved fitting the distributors to the car for a full rolling road test which confirmed the car was ready to race.

Ferrari 225s Piston.

When parts for rare cars become obsolete, sometimes the only choice is to recreate them. When you recreate something there is always a worry about accuracy, but the recreation of these Ferrari pistons should dispel any such concerns. We needed a full set of pistons and con rods, but we only had one piston as the rest had been destroyed. We used this one good piston as our starting point by scanning it using our metrology grade 3D scanner, and created a CAD model from the scan. We could then implement and design changes to the original piston before the CAD model was used by a reputable manufacturer to directly machine a new set of pistons and con rods.